Advanced Robotics in the Manufacturing Industry

The manufacturing industry has experienced a significant revolution with the introduction of advanced robotics. These robots, equipped with cutting-edge technologies and capabilities, have revolutionized the way products are manufactured. They have led to increased efficiency, productivity, and accuracy, while also reducing costs and improving overall product quality. In this blog post, we will explore the advancements in robotics in the manufacturing industry and their impact on the sector.

One of the significant advancements in robotics in the manufacturing industry is the development of collaborative robots, also known as cobots. These robots can work alongside human workers, assisting them with repetitive and physically demanding tasks. Cobots are equipped with advanced sensors and artificial intelligence algorithms, allowing them to understand their surroundings, avoid obstacles, and interact safely with humans. This collaboration between humans and cobots has led to increased efficiency and productivity on factory floors.

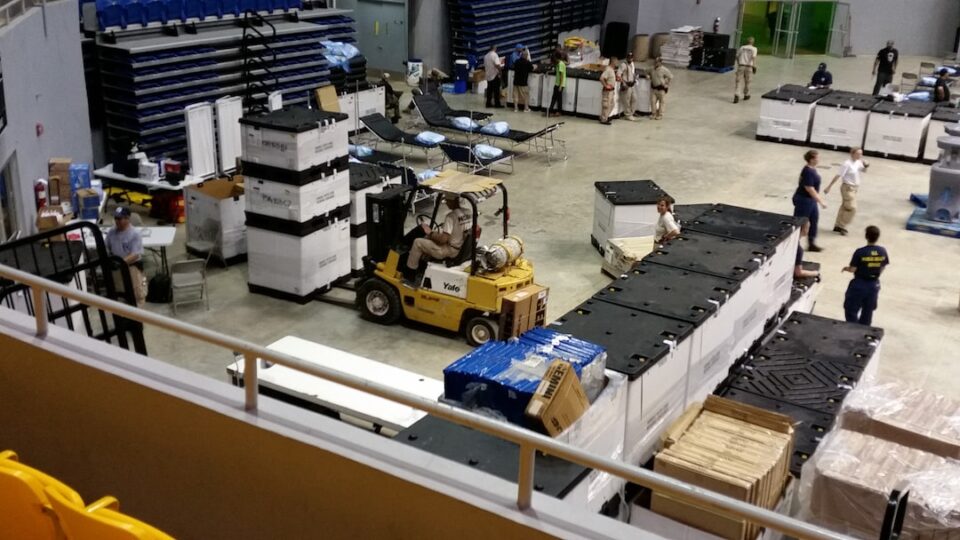

Another significant advancement is the introduction of autonomous mobile robots (AMRs) in manufacturing facilities. These robots are designed to navigate autonomously within a factory floor, transport materials, and interact with various machines and processes. AMRs can optimize material flow, reduce manual labor, and ensure smooth operations. They are equipped with advanced sensors, cameras, and algorithms, allowing them to adapt to changing environments and avoid collisions. By incorporating AMRs into manufacturing processes, companies can significantly increase productivity and flexibility.

Moreover, advancements in robotic vision systems have revolutionized quality control in manufacturing. Robots equipped with vision systems can perform inspections and detect defects, eliminating the need for manual inspections. These vision systems use advanced algorithms and sensors to identify defects, measure dimensions, and ensure product consistency. With robotic vision systems, companies can achieve higher levels of accuracy and quality, reducing costs associated with defects and rework.

Additionally, robotic arms equipped with advanced gripping technologies have improved the handling and manipulation of complex materials and objects. These arms can adapt to the shape, weight, and fragility of various products, allowing for more efficient and precise handling. They can be programmed to perform intricate tasks, such as assembly, welding, and pick-and-place operations, with high accuracy and repeatability. By employing robotic arms, manufacturers can enhance productivity and reduce the risk of human errors.

Furthermore, the introduction of machine learning and artificial intelligence has empowered robots to learn and adapt to new tasks and environments. These technologies enable robots to analyze large amounts of data, make predictions, and improve their performance over time. For instance, a robot can learn from an experienced operator and replicate their actions in a simulation. This ability to learn and adapt makes robots more versatile and easily deployable across different manufacturing processes.

Apart from productivity improvements, advanced robotics in the manufacturing industry have also led to improved worker safety. Robots can handle hazardous or physically demanding tasks that pose risks to human workers. By automating these tasks, manufacturers can avoid accidents and protect their employees. Collaborative robots, in particular, are designed with safety in mind, incorporating features such as force sensors and speed limitation. The integration of robots into a manufacturing environment thus creates a safer and healthier workplace for human workers.

The future of advanced robotics in the manufacturing industry is promising. Ongoing research and development aim to further enhance the capabilities of robots, making them more intelligent, versatile, and adaptable. As robots become increasingly capable of complex tasks, they will play a crucial role in transforming the manufacturing industry, driving innovation, and delivering higher efficiency and productivity.

In conclusion, advanced robotics have brought significant advancements to the manufacturing industry. Collaborative robots, autonomous mobile robots, robotic vision systems, advanced gripping technologies, and machine learning have all contributed to increased productivity, efficiency, and product quality. Moreover, robots have improved worker safety by handling hazardous tasks. As automation and robotics continue to evolve, manufacturers must embrace these technologies to stay competitive and reap the benefits they offer. The future of manufacturing is undoubtedly driven by advanced robotics.